The primary use for Personal Protective Equipment (PPE) is that it helps establish the safest feasible working situations within an industrial environment. There are several different kinds of hazards associates with working within such an industrial environment, including but not limited to; chemical exposure, heavy machinery operations, falling objects, noise, and electrical hazards. By using PPE, employees have a lower chance of receiving an injury from these hazards and can perform their jobs in the safest environment possible.

What is PPE?

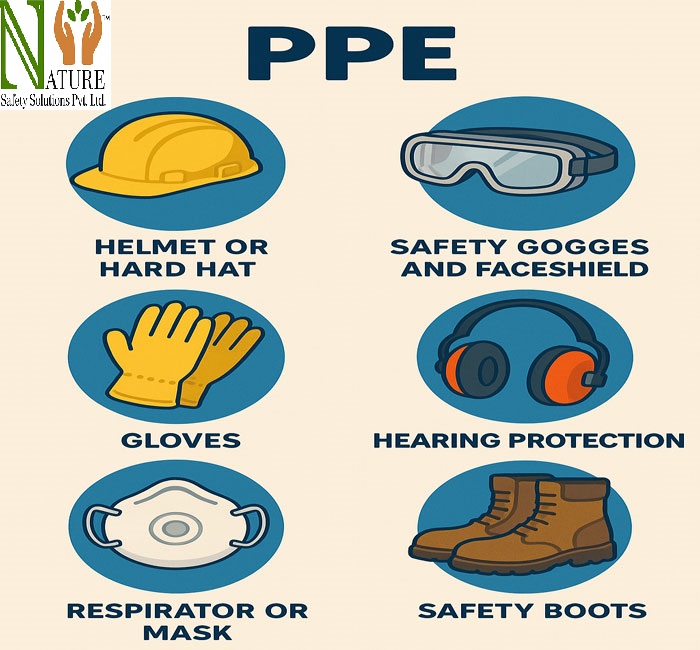

PPE refers to the equipment and clothing designed to protect workers from health and safety hazards. This includes items such as:

Helmets or hard hats – to protect the head from falling objects or impacts.

Safety goggles and face shields – to guard the eyes and face against chemical splashes or flying debris.

Gloves – to protect hands from cuts, burns, chemicals, or contamination.

Hearing protection – like earplugs or earmuffs in noisy environments.

Respirators or masks – to protect the lungs from dust, fumes, or toxic gases.

Safety boots – with steel toes and slip-resistant soles to prevent foot injuries.

Protective clothing – such as flame-resistant coveralls or high-visibility vests.

The Significance of PPE within Industrial Used Spaces

Assist in Decreasing Injuries & Deaths at Work

Personal protective equipment serves as the last mechanism, a last resort to hazards not able to be controlled completely by engineered or administrative regulations.

Adhering to Regulatory Safety Standards

The U.S Government and Safety Agencies such as OSHA (Occupational Safety and Health Administration) have required that personal protective equip become the norm in many areas of industrial work. Nonadherence to these standards could result in monetary fines or closures.

Enhanced Efficiencies & Confidence

Workers will typically be able to focus at work with more confidence when they feel protected at their jobs and therefore there is often a correlation between employee productivity.

Prevention of Long-term Appropriateness of Health to Worker

Repeated exposure to hazardous materials/physicals or noise at work without PPE could create additional chronic health based problems for the worker. The use of PPE also provides the worker opportunity to buy an additional period of productive health, thereby delaying chronic health concerns or disabilities from occurring.

Issues Affecting Personal Protective Equipment

Despite the importance of Personal Protective Equipment (PPE), many times the appropriate use does not happen or there is a lack of use due to several reasons which include:

- Not having received proper training to properly utilize PPE

- Discomfort, which results in improper use or non-compliance

- Improper maintenance and/or not replacing PPE if damaged.

Continuous training, proper fitting and regular inspection(s) of PPE will assist in eliminating most of these reasons.

Read also:-